The market today is more competitive than ever. The players have added new attributes to competition and the value scoring isn’t limited to quality and price. Today, you need to achieve holistic excellence to make a name for yourself.

But how can you evaluate if your business activities are providing the most value to your customers while maintaining good profits? How is value generation for both customers and shareholders envisioned?

Enter the concept of value chain.

Value chain answers every question pertaining to how a business provides value to its customers and itself. It is a useful technique to evaluate business processes and identify chances for innovation.

But what is value chain and how to develop it? Let’s find out.

What Is A Value Chain?

A value chain is a series of activities carried out by an organisation to create and deliver value to the customers. It provides a company a competitive advantage by relieving the customers’ pains and providing them with exactly what they want.

It includes all the activities involved in transforming a product from idea to reality; that is, right before the procurement of raw materials till the time the product reaches its end consumer.

But, what is customer value?

The benefits that a customer receives in monetary terms in return for the price paid for a market offering is known as customer value. To create and deliver this “value”, a company conducts a series of activities, this series of activities is called value chain.

The concept of value chain was pioneered by Harvard Business School professor Michael Porter in 1985. He visualised the concept and discussed it in his influential book Competitive Advantage: Creating and Sustaining Superior Performance.

Value Chain Vs Supply Chain

Supply chain and value chain are two processes involved in bringing goods from the design board into the hands of customers. Hence, they are often confused to be the same concept.

However, both of them approach the process from a different perspective and with different goals.

Value Addition

The main distinction between a supply chain and a value chain is that a supply chain does not have any value added. All that is being done in a supply chain is a conveyance, that is, a commodity or material is taken from one business and sent to the other, while the main function of a value chain is to add value to the commodity so that it can be presented to the customer.

Origin

The supply chain concept originated from operational management, while the value chain concept comes from business management.

Concept and Objective

The supply chain activities are planned and controlled through the process of supply chain management. This cross-functional system aims to ensure complete customer satisfaction. Whereas the ultimate goal of a value chain is to give a business a competitive edge by increasing productivity while keeping costs reasonable. For this, it uses value chain analysis.

Supply chain = supplying products

Value chain = delivering value

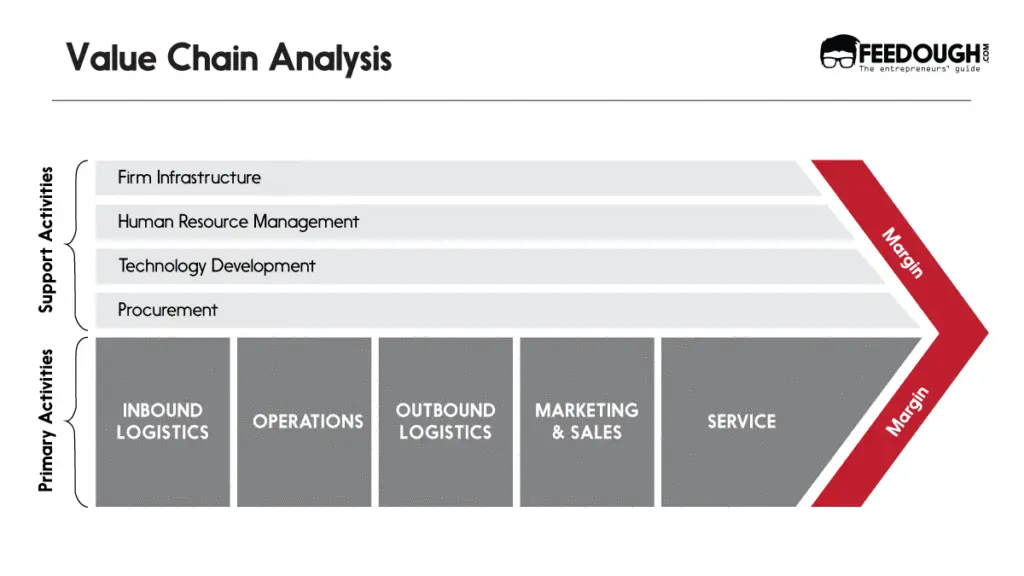

Porter’s Value Chain Model

Porter’s value chain model examines processes involved in the transformation of inputs into outputs. It sees a company as a chain of value-creating activities.

Porter used the concept to demonstrate how businesses add value to their raw materials to create products that are then sold to the customers.Thus, it’s crucial to maximise value at each stage of a company’s operations.

He represented a chain of activities common to all businesses, which he divided into primary and support activities. These activities are used as “building blocks” by businesses to produce a valuable product or service.

Primary Activities

Primary activities add value and give a business a competitive edge, meeting external demands. It includes all the actions that are directly involved in the production and selling of the product like procurement of raw materials, transforming it into finished product, its delivery, marketing, and services.

Inbound logistics

It encompasses actions and processes involved in getting, distributing, and storing products internally. It also involves relationships with suppliers as it is important in creating value.

Examples include material storage, warehousing, inventory management, vehicle scheduling, and returns to supplier

Operations

It includes all the processes involved in the transition of raw materials to the final product. This include processes like manufacturing, packaging, assembly, equipment repair, testing, printing, and facility operations.

Outbound Logistics

It includes activities involved in delivery of the final product to the customer, like collecting, storing, and physically delivering the product to customers. It also involves overseeing a company’s internal systems as well as external systems from consumer organisations.

Examples include finished goods warehousing, delivery vehicle operations, order processing, and scheduling.

Marketing & Sales

Marketing and sales activities involve purchase of finished goods by customers and the incentives offered to persuade them to buy the company’s products.

Advertising, branding, quoting, channel selection, channel relations, and pricing are included in marketing and sales that aim to maximise visibility, attract a marketing audience, and communicate why a buyer should buy a product or service.

Services

It involves activities that are intended to maintain the value of products and improve the customer experience. It includes add-on services, installation, warranties, refunds, and returns. The importance of after-sales service is equal to that of promotional activities.

Support Activities

Support activities are mostly centered on addressing internal needs and play an auxiliary role in primary activities. There are four support activities and increasing the efficiency of any of the four support activities benefits at least one primary activity.

Procurement

It includes processes involved in the acquisition of raw materials, tools, and other consumable goods, as well as machinery, laboratory equipment, and office equipment. It also includes actions involved in finding suppliers and negotiating contracts for goods and services.

Technological Development

Technology is used at different stages of the value chain to achieve a competitive advantage by increasing productivity or lowering production costs. Technological development includes activities relating to machinery, hardware, software, procedures, cybersecurity, and technological expertise. Research and development teams are often included in this category.

Human Resources (HR) Management

It consists of activities involved in recruiting and retaining staff (like training, building, motivating, rewarding) who will help develop, market, and distribute the product as per the firm’s business plan. Nowadays, many companies devote a Talent Management department within HRM that recruits and trains the best university graduates.

Infrastructure

It refers to a company’s support systems and involves functions that enable an organisation to run its day-to-day operations. It includes activities like general (strategic) management, planning, finance, accounting, legal, government relations, and quality management.

These elements of a value chain contribute to the equation that leads to margin calculation. Now, what are the margins?

The revenue earned by the value chain is referred to as margins.

Margin = Value Created and Captured – Cost of Creating that Value

What Is Value Chain Analysis?

Value chain analysis is a multi-purpose process that assesses a company’s primary and support activities to understand costs, identify the activities that add the most value, and set the company apart.

It aims to build or improve a competitive advantage for a business and assists in identifying places where it can improve productivity and profitability in order to increase margins.

How To Conduct A Value Chain Analysis?

Value chain analysis necessitates research and might be time-consuming to complete. But it can make a company reach milestones. Some steps involved in creating a value chain analysis are outlined below.

Identifying Value Chain Activities

The first task is to identify each step in the value chain.

In the case of primary activities, a company should specify sub-activities that create value.

For support activities, companies should determine sub-activities that build value within each primary activity.

This involves correct identification of direct activities (activities that create value by themselves), indirect activities (activities that help direct activities to run smoothly), and quality assurance (activities that ensure that direct and indirect activities meet the required standards).

Identifying And Analysing The Cost And Value Of Activities

The next step is to evaluate the value that each activity contributes to the process, as well as the associated costs.

Is the activity time-consuming? What is the price of raw material?

Using similar questions, a company can determine which practices are cost-effective and which are not. As far as value is concerned, the value must always be examined from the perspective of the consumer.

Do the materials used to build a product make it more durable or luxurious for the user? Will a company benefit from network effects and increased business if they have a certain feature?

Answering such questions helps to avoid wastage of resources on a function or part of a product or service that does not help the consumer add value.

Identifying Opportunities For Competitive Advantage

Now the company needs an overview of where it excels and where organisational changes should be made. It should begin with improvements that require only small adjustments but have a large effect. Once a company has defined and implemented the easy wins, it can move on to the more difficult tasks that might be impeding production.

In order to gain competitive advantage, a company can approach value chain analysis either by cost advantage or by differentiation advantage.

Cost advantage

This approach is used when a company attempts to compete on cost. This strategy aims to minimise the costs of the activities or the total amount of resources used as well as to develop an understanding of what factors drive those costs.

Thus, businesses should classify the cost drivers for each activity. Cost drivers mean anything that influences the cost of an activity or procedure like linkages between activities, geographical location, policy choices.

After determining the cost drivers, a company must look for ways to optimise and reduce it. The lower the cost, the more a company can push its prices down and get a cost advantage over competitors.

Differentiation Advantage

This approach is used by companies who want to create differentiated goods or services. It takes into account all of the activities that the customer values the most using value drivers. Value drivers are similar to cost drivers, but they refer to features that customers value other than low prices like meeting customer expectations.

A company can implement this strategy to ensure that they add value and can be sustained over time as the more valuable differentiation a company has from its competition, the merrier it is for its business in the long term.

For this, a company must identify cheaper suppliers, encourage its staff with various merit-based approaches, and integrate multiple digital solutions.

Finally, there are two stages to consider when evaluating value chains.

- Interrelationships between the firm’s activities (These correlations are crucial to gaining a competitive advantage from the value chain framework).

- Relationships between internal operations and external organisations that are part of the firm’s extended value chain.

Advantages Of Value Chain Analysis

The value chain aids companies to identify and evaluate sources of cost efficiency, both positive and negative, and benefits a company in several ways.

- Boosts profit: It can improve a company’s profit margins because of efficient logistics and distribution. Increased consumer value and decreased redundancy provide the highest possible revenue to the business. For example, the marketing and after-sales facilities of Apple draw more customers and persuade them to purchase goods at higher rates.

- Enhances the quality of the offering: It can improve the market’s quality and make it more competitive. The continuous reviewing of primary and support activities and a knowledge of consumers’ tastes and preferences improves the quality of products due to heavy competition.

- Eliminates waste and provides stronger brand recognition: It helps to reduce a company’s cost by eliminating things that cost more or take up too much of an employees’ time. Also, it improves a brand’s image by consistently delivering value to the customers and looking for both differentiation and cost advantages.

- Increases sustainability: It can increase a company’s long-term adaptability and sustainability while enhancing its valuable offerings. This can be done by mapping the value chain process and eliminating menial activities that don’t contribute to the final product.

Disadvantages Of Value Chain Analysis

Although there are many benefits to performing a value chain analysis, there are some significant disadvantages as processes that seek to increase work efficiency and add value while reducing costs can have some drawbacks.

- Loss of target: The larger strategic view can be lost if too much attention is paid to microdata. Value chain analysis aims is to analyse a company’s operations, segment by segment but sometimes it’s easy to lose sight of how the various events interact in general.

- Difficulty in developing chains: Even though value chain analysis is conducted in different stages, its creation is a difficult task. The data collection process is slow and tedious, determining what adds value or not can sometimes be subjective (due to unreasonable customer behavior), and deploying the plan can be labor-intensive and time-consuming.

- High implementation costs: Value chain analysis is a never-ending operation, as competition never stops, and constant benchmarking is needed to be one step ahead of others. The implementation cost for an organisation that has never used value chain analysis before can be high.

- Maintaining the process can be a difficult task: To design a value chain is just half the battle. It can take up so much time that the staff won’t be able to concentrate on other tasks.

Go On, Tell Us What You Think!

Did we miss something? Come on! Tell us what you think about our article on value chain in the comments section.

An avid reader and economics enthusiast who is always eager to learn. Prachi is an aspiring leader who believes in what she does. Besides reading , she is fond of baking , dancing and travelling.